Know your Foam.

Not all foams are created equal. There are different types of foam, with different chemical components, which come together to create different tactile properties with different applications. To the uninitiated, it can be overwhelming.

That’s why this page exists. We’ve been working with the material since its commercial inception in 1952. In almost 70 years of business, we’ve gained a level of expertise that is matched by few in our industry. This page is designed to act as a primer explaining some of the finer details of a substance that is, honestly speaking, an amazing example of chemistry and engineering.

Click below to check out the different properties of foam, the science behind them, and the many ways our products can be used.

What Kind of Foam is it?

We should probably begin with some clarification. There are a lot of products that fall into the category of “foam”. Things like packing peanuts, Yoga Mats, and laptop packaging all use it as a descriptor. Are they the same thing? And, do we sell each of these items?

The short answer to both questions is no. The products mentioned are made using polystyrene, cross-link, and polyethylene foams respectively. What we sell is polyurethane foam. Polyurethane foam is ideal for re-upholstery projects, bedding, and similar applications. At Bestway, our foams tend to fall into one of three markets: Re-upholstery, Bedding, and Crafting.

Re-Upholstery: Our bread and butter. Products like our Seat Ultra line provide extremely durable options for small re-upholstery companies and do-it-yourselfers to restore high quality couches and seat cushions.

Bedding: While Bestway Foam does not recommend using our foam for DIY beds, we do have a lot of experience with mattresses. We have been supplying into the bedding industry for almost 70 years. The toppers we sell are made using some of the highest quality foams on the market.

Crafting: From one off projects to museums and professional stop motion illustrators, we’ve had the unique privilege of working with some amazingly creative individuals to help bring their artistic visions from concept to completion. Our Seat Plus is especially suitable for creating small, intricate designs.

What’s in a foam?

When looking at what foam to purchase, there are two really important factors to bear in mind: Density and Firmness. As metrics they are commonly misunderstood. The next two sections address them in a little more depth to help you make the most informed decision.

Firmness

When we refer to the firmness of our foam, we aren’t just talking about a subjective experience of how it feels in your hand. Rather, we refer to a technical measurement called IFD or Indentation Force Deflection. What this measures is the number of pounds of weight (or force) required to condense a 4-inch thick sample of the foam to 75% of its original height. Therefore, the higher the IFD, the firmer the foam.

That said, while IFD is the scientific measure of firmness, the level of resiliency or tactile properties of the foam type can also sometimes play into an individual’s perception of firmness or softness. Thus, when we consider the feel of the foam, it’s not always apples to apples. This is especially noticeable when selecting foam toppers. Consequently, we always encourage encourage our customers to order samples beforehand, in order to get a “feel” for what kind of foam will best suit their purposes.

FIRMNESS ≠ DENSITY

The other important metric to remember is density. Now, you may be thinking, “Wait a minute — aren’t density and firmness the same thing?” This is not an uncommon assumption, but it’s not really accurate. While Firmness indicates the amount of support you will get in a foam, density is better viewed as an indicator of the foam’s durability.

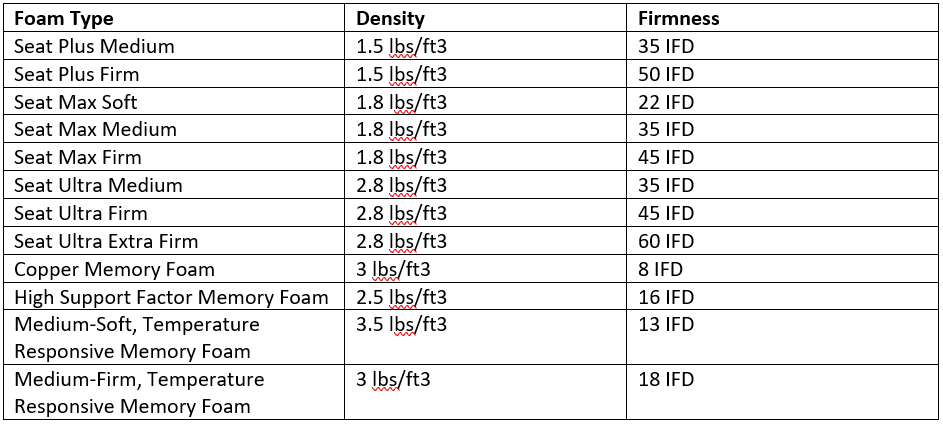

All of our foams can be found here, listed with their respective densities and firmness ratings.

When you think about it, this makes sense. Foam density is measured in pounds per cubic foot, so, the denser the foam, the more material went into making it. This — in turn— translates to a longer-lasting product. Thus, the more weight in a given cubic foot, the higher the quality. More material= longer performance.